Teflon Hose Smooth Bore (PTFE)

SAE 100R14

The PTFE hose core is manufactured from PTFE. No pigments or additives are incorporated thus giving the hose liner a translucent appearance free from any contamination.

The wire braiding (1 or 2 wire available) is produced from AISI 304/S15 or BS970 1970 quality hard drawn tensile stainless steel wire. Reduced static versions of all hoses are available for applications where electrically resistive fluids are being transferred at high flow rates.

The PTFE hose core is manufactured from PTFE. No pigments or additives are incorporated thus giving the hose liner a translucent appearance free from any contamination.

The wire braiding (1 or 2 wire available) is produced from AISI 304/S15 or BS970 1970 quality hard drawn tensile stainless steel wire. Reduced static versions of all hoses are available for applications where electrically resistive fluids are being transferred at high flow rates.

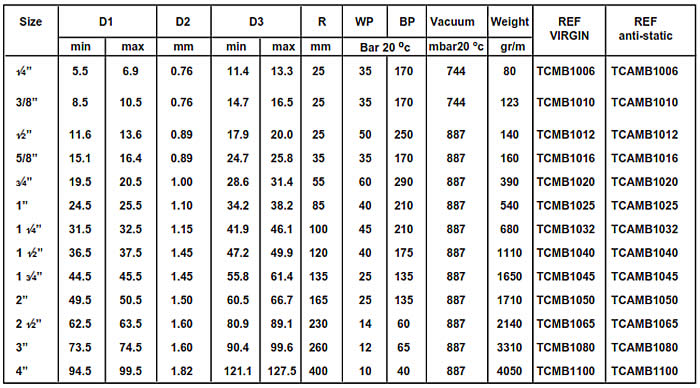

Smooth Bore HoseAll of the hoses in the following range are fully approved to the SAE specification and are available from Pacific Hoseflex today. We feel that this will become the global size range for PTFE hoses and recommend that your smooth bore hose demands are selected from this range. If the coupling size restricts your choice we have three further ranges of smooth bore hoses for you to select the exact size that best suits your requirement.

The standard wall products are not recommended for steam-cold water cycling.

We recommend the Heavy Wall range for the most demanding applications including intense thermal cycling.

The standard wall products are not recommended for steam-cold water cycling.

We recommend the Heavy Wall range for the most demanding applications including intense thermal cycling.

- Please note that Hoseflex PTFE HOSE meets and exceeds the stated working and burst pressure values of the SAE specification.

- Please note Standard working pressures are 3:1 Safety Factor

- Please note all pressures stated are static

EASYFLEX Convoluted Hose

Easyflex was developed to simplify the assembly of convoluted PTFE hose using standard hydraulic fitting.

The tube is manufactured in a seamless, extruded convoluted PTFE.

This process allows the manufacture of maximum lengths of 60 meters and gives control over Product quality.

When you have an application restricted by space, Brierley Hose & Handling has the ideal solution.

Easyflex was developed to simplify the assembly of convoluted PTFE hose using standard hydraulic fitting.

The tube is manufactured in a seamless, extruded convoluted PTFE.

This process allows the manufacture of maximum lengths of 60 meters and gives control over Product quality.

When you have an application restricted by space, Brierley Hose & Handling has the ideal solution.

Teflon Encapsulated

Construction:

A helically convoluted PTFE (polytetrafluorethylene) inner tube, medium wall, with an outer cover of AISI 304 high tensile stainless steel braid.

Properties:

The hose is virtually resistant to all chemicals, except molten alkali metals or halogens at elevated temperatures. It is non-stick and easy to clean with

a temperature range of -70º C to +260º C. The mechanical resistance for vibrations and flexing is excellent. The product is chemically inert, nonageing

and has a very good U.V. resistance. The low co-efficiency

of friction ensures low pressure drop.

It is non-flammable and FDA. approved for food, cosmeticand pharmaceutical applications.

Typical Applications:

Encapsulated PTFE is recommended on all tafted flange

assemblies when pressure or vacuum are applied.

Construction:

A helically convoluted PTFE (polytetrafluorethylene) inner tube, medium wall, with an outer cover of AISI 304 high tensile stainless steel braid.

Properties:

The hose is virtually resistant to all chemicals, except molten alkali metals or halogens at elevated temperatures. It is non-stick and easy to clean with

a temperature range of -70º C to +260º C. The mechanical resistance for vibrations and flexing is excellent. The product is chemically inert, nonageing

and has a very good U.V. resistance. The low co-efficiency

of friction ensures low pressure drop.

It is non-flammable and FDA. approved for food, cosmeticand pharmaceutical applications.

Typical Applications:

Encapsulated PTFE is recommended on all tafted flange

assemblies when pressure or vacuum are applied.